Manufacturers

Our manufacturers are high quality well based firms from China, Taiwan and South Korea. We work together on achieving our joint goal of providing the best service possible. Our wide network of highly professional manufacturers and stable suppliers allows us to link the most suitable suppliers to our clients’ demands, making a Win-Win cost-efficient situation.

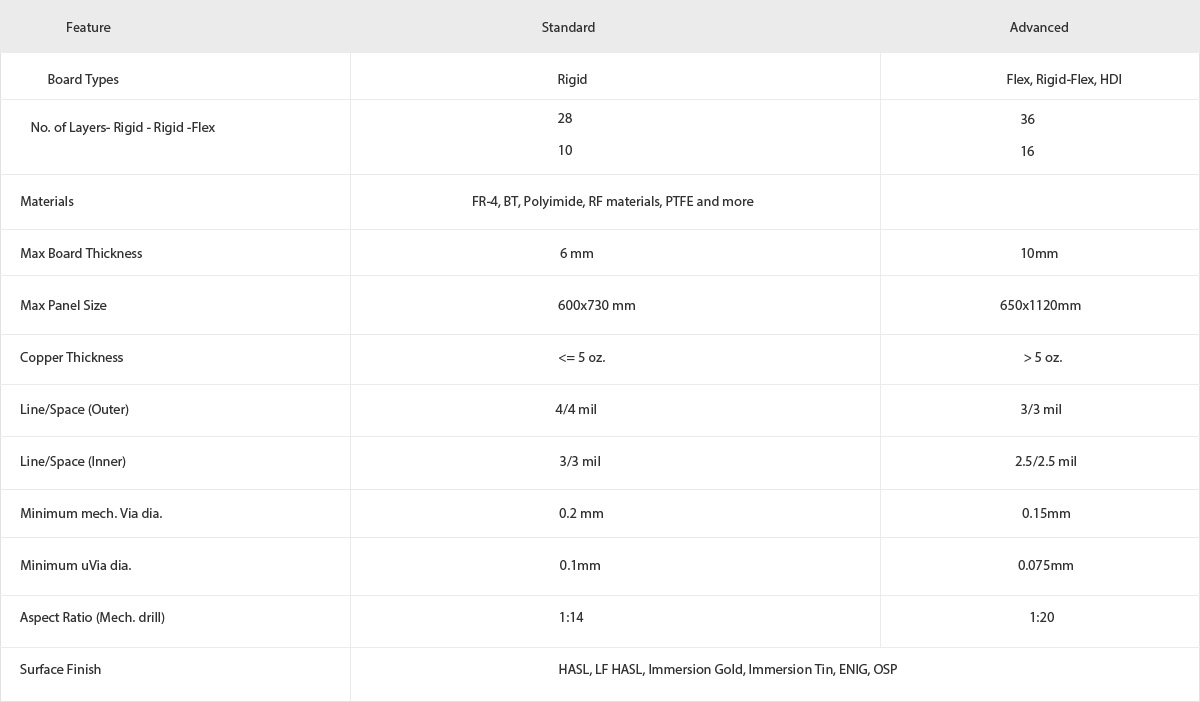

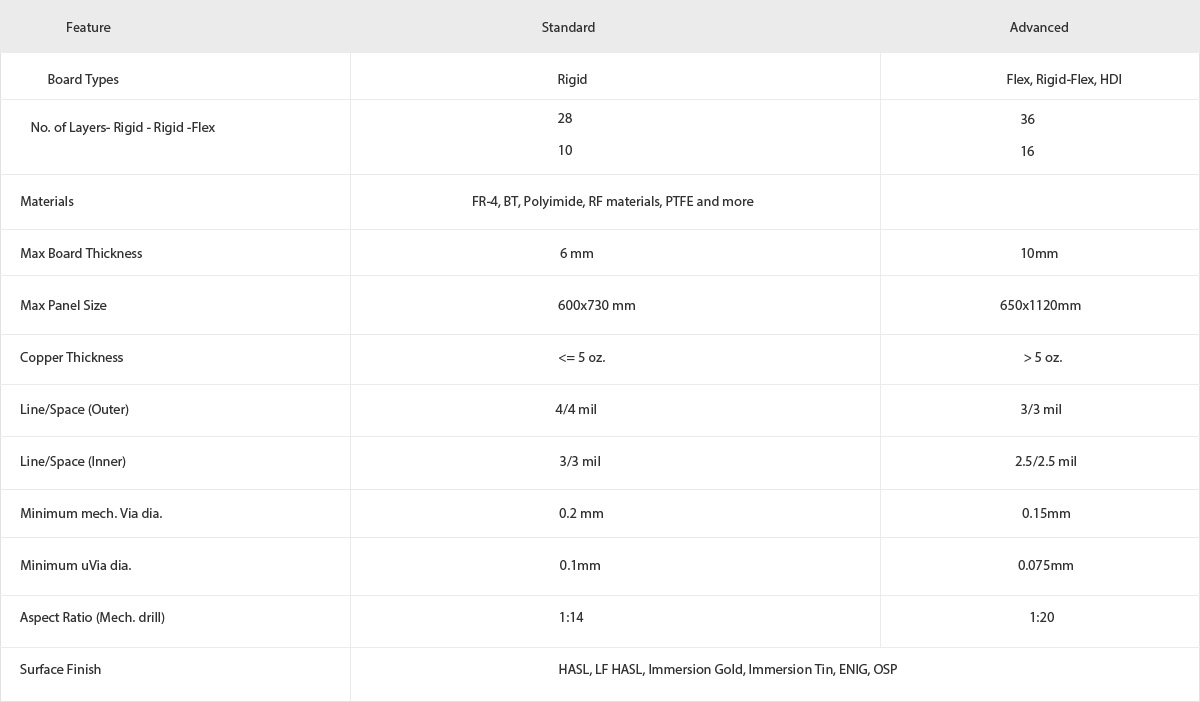

Our PCB manufacturers’ meet the following capabilities:

We provide Printed Circuit Board Assembly services for many different range of products . developing the latest PCBA and surface mount (SMT) capabilities including support for :

• 0201 components, fine pitch and high count BGAs, Chip on Board, fiber optics, RF microelectronics, press fit connectors

• Hybrid processes (tin-lead and lead-free), pin through hole, wave & selective soldering, double and single sided reflow, wide body and backplanes

• Quick turn prototype assembly, RoHS compliance certification, conformal & parylene coating, laser marking

• Inspection and testing using the latest SPI, AOI, Flying probe and X-Ray equipment

• Comprehensive electrical testing and test system development for boundary scan, in-circuit test (ICT), functional test and burn in test (BIT)

Quality-Driven Printed Circuit Board Assembly Processes

To ensure our parts are delivered compliant to even the strictest requirements, our Printed Circuit Board Assembly Division typically provides the following services:

Review and check specifications to ensure the SMD components are properly packaged, stored and handled per the MSL classification.

Identify sensitive components to avoid thermal and mechanical damage during SMT processes in accordance to the latest J-STD-020 standards, including compliance at higher temperatures for Pb-free and lower temperature

Sn-Pb assemblies.

Review components specifications for ESD, MSL handling and reflow profile in accordance to IPC J-STD-020 standard.

Evaluate the PCB layout including board thickness, pad size, surface finishing, solder mask alignment, component density, pitch and orientation.

Design the stencil thickness and hole size, use of solder paste material and reflow profile setup to ensure the solder joint meets IPC-A-610 standards.

If needed, fine tune the SMT process based on AOI, X-ray inspection and testing data.

Our PCB manufacturers’ meet the following capabilities:

We provide Printed Circuit Board Assembly services for many different range of products . developing the latest PCBA and surface mount (SMT) capabilities including support for :

• 0201 components, fine pitch and high count BGAs, Chip on Board, fiber optics, RF microelectronics, press fit connectors

• Hybrid processes (tin-lead and lead-free), pin through hole, wave & selective soldering, double and single sided reflow, wide body and backplanes

• Quick turn prototype assembly, RoHS compliance certification, conformal & parylene coating, laser marking

• Inspection and testing using the latest SPI, AOI, Flying probe and X-Ray equipment

• Comprehensive electrical testing and test system development for boundary scan, in-circuit test (ICT), functional test and burn in test (BIT)

Our PCBA providers meet the following capabilities:

| Feature | Feature | value |

| Assembly | Position accuracy | 20 um |

| Components type | BGA, uBGA, 0201,01005, QFP, POP, QFN, DFN | |

| Assembly types | TH, SMT, Mixed, Double sided | |

| Max PCB dimensions: 400mm x 400mm | ||

| Soldering types | Reflow, Wave-Solder, Leaded, Lead free | |

| Additional Capabilities | Conformal coating, Under Fill, Component securing, Press-Fit | |

Quality-Driven Printed Circuit Board Assembly Processes

To ensure our parts are delivered compliant to even the strictest requirements, our Printed Circuit Board Assembly Division typically provides the following services:

Review and check specifications to ensure the SMD components are properly packaged, stored and handled per the MSL classification.

Identify sensitive components to avoid thermal and mechanical damage during SMT processes in accordance to the latest J-STD-020 standards, including compliance at higher temperatures for Pb-free and lower temperature

Sn-Pb assemblies.

Review components specifications for ESD, MSL handling and reflow profile in accordance to IPC J-STD-020 standard.

Evaluate the PCB layout including board thickness, pad size, surface finishing, solder mask alignment, component density, pitch and orientation.

Design the stencil thickness and hole size, use of solder paste material and reflow profile setup to ensure the solder joint meets IPC-A-610 standards.

If needed, fine tune the SMT process based on AOI, X-ray inspection and testing data.